Optional Features

Automatic Tube Cleaning System

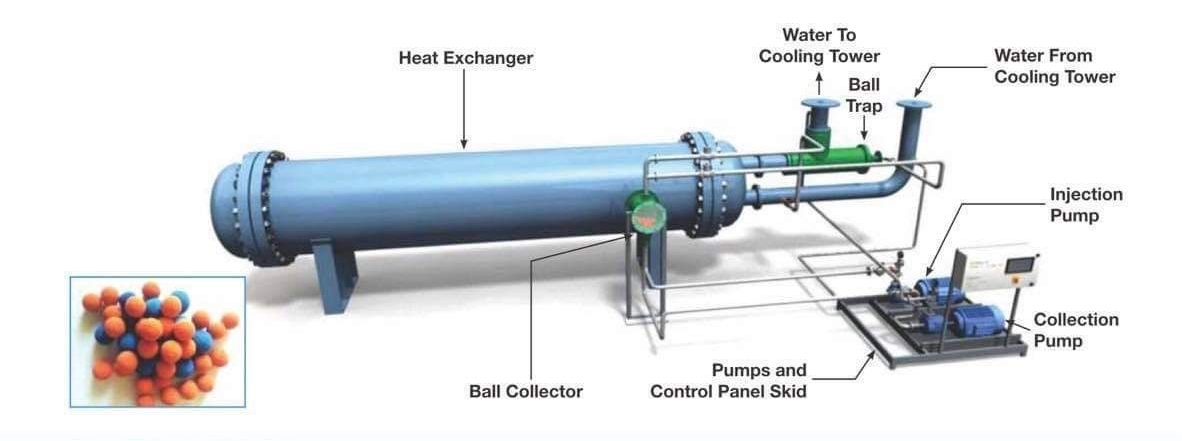

Ball Type Automatic Tube Cleaning System

System Description

The system uses sponge balls to keep the heat exchanger tube clean. The sponge balls are injected almost simultaneously at the heat exchanger tube sheet with the help of an injection pump, thereby giving effective spread to the sponge balls in various tubes. The sponge balls would pass through the tubes and clean the fouling, scales, and deposits inside the tubes.

Once the sponge balls come out of the heat exchanger tubes, those are collected at the ball trap and sent back to the ball collector with the help of the collection pump. The entire process is a batch operation automatically controlled by PLC and occurs 2-3 times in an hour. These pumps run hardly for a few seconds for injection and collection of sponge balls.

The system is designed to have a long life and for trouble-free operation.

Features & Benefits

- Fully automatic system; no manual intervention is required.

- Frequent ball circulation prevents scale formation or foiling inside the tubes.

- Gives energy savings to the tune of around 10%.

- On-line system, thus avoiding costly shut down.

- Avoids brush & chemical cleaning, thus enhancing tube life.

- Operating energy costs are very low.

- Single skids can accommodate multiple chillers.

- Designed for minimal pressure drop.